Description:

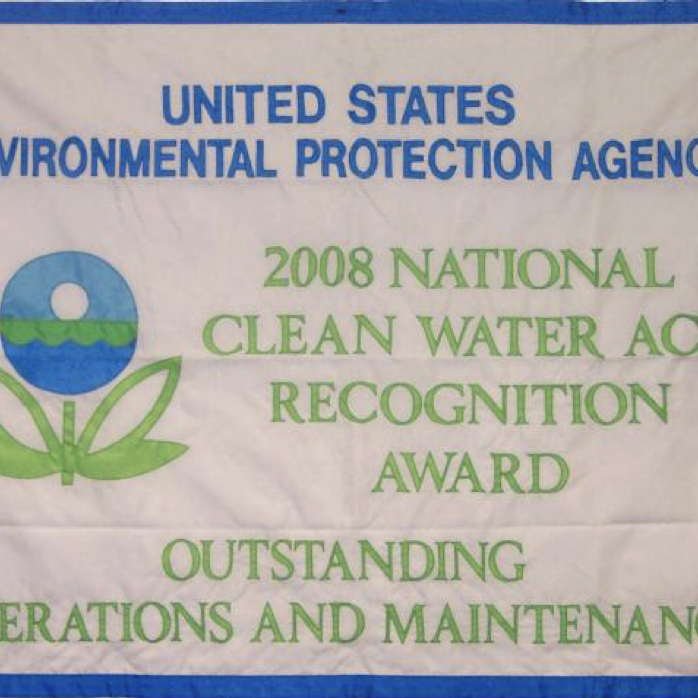

The Village of Waterville Wastewater Treatment Facility has been operational since 1970. At that time everything was new, buildings, process tank and distribution lines and manholes. The original cost was $1,575,000.00. The plant ran for 27 years with only minor changes done before a plant modification project in 1997. That project cost was approximately $880,000.00. The compost building was added in 2000. The plant still has a design flow of 300,000 gallons/day. The plant serves about 1,600 people. The plant is an activated sludge, extended air process plant. The facility has won many awards from local levels, state level and even national level. The facility has set high standards to run by and is always open for the public pickup of compost or to take a tour.

Responsibilities

The average person contributes between 50-100 gallons of wasterwater each day. The wastewater that flows to our plant is 99% water and 1% waste. This wastewater flows to our facility by gravity – no pumping. Once this wastewater reaches the plant it goes to the intake structure which removes 40-60% of the incoming wastewater solids. The wastewater, now called influent, goes through a comminutor, which acts as a giant garbage disposal.

After the comminutor, the influent then goes through the grit chamber that now removes the heavy organic particles and prepares the influent for the process. The influent then goes to the wet well or pump house and is now pumped to the tank by three 275 gpm pumps. The tank is the secondary treatment in the process. The tank consists of two aeration basins, one clarifier, and two digesters. The influent is pumped into the aeration basin where it is given large amounts of air to help mix the wastewater bacteria and other microorganisms. The air helps speed up the growth of helpful microorganisms which consume harmful organic matter in the wastewater. Once the influent goes into the aeration tank it is then called mixed liquor.

The mixed liquor consists of many microorganisms working to consume or eat most of the waste material. This mixed liquor moves through the aeration basins and then enters the center of the clarifier and then falls to the bottom of the clarifier. These solids in the bottom of the clarifier thicken and eventually are removed to the digester. The clear clean water rises in the clarifier and goes over the veirs on the outer top edge of the clarifier.

This clear water is now called effluent and is now 90-99% clean and ready to go the receiving stream. The excess solids in the bottom of the clarifier are removed daily by means of wasting solids to the digester. These solids are now called sludge or biosolids. The biosolids are thickened and stabilized in the digester and eventually pumped to a belt press.

The belt press removes the excess water from the biosolids, with the extracted water going back into the process, and the the wet biosolids going to the compost building. In the compost building the wet biosolids are mixed with woodchips to make compost. The compost goes through a biological process of organic decompositon under a controlled environment and is reduced to its most stabilized form. The compost is then screened and when finished a class 1 compost is made. The compost is then given to the Village residents for use as a soil amendment and works great on lawn areas, tree planting and flower gardens.

Programs/Activities

The facility is open for public pickup of compost (call first) and available for touring. If you or your organization would like a tour or more information about the facility or to pick up compost please call 315-841-4445 or email watstp1@villageofwaterville.org.